DEPARTMENT OF FUEL, POLYMER, AND POLYGRAPHIC MATERIALS TECHNOLOGIES

SHEI Ukrainian State University of Chemical Technology is the only specialized higher education institution in the field of chemistry and chemical technology in Ukraine. During its existence, since 1930, about 60 thousand highly skilled specialists have been trained. Of these, over 50 have become academics from various academies, and 15 are state prize winners.

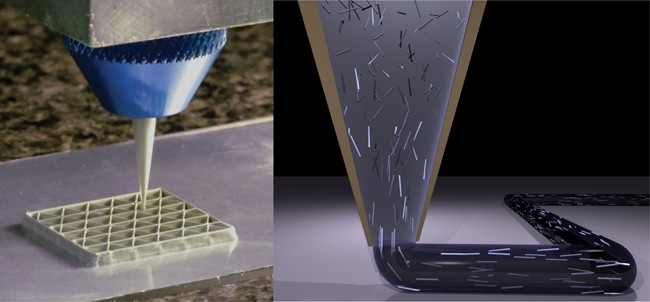

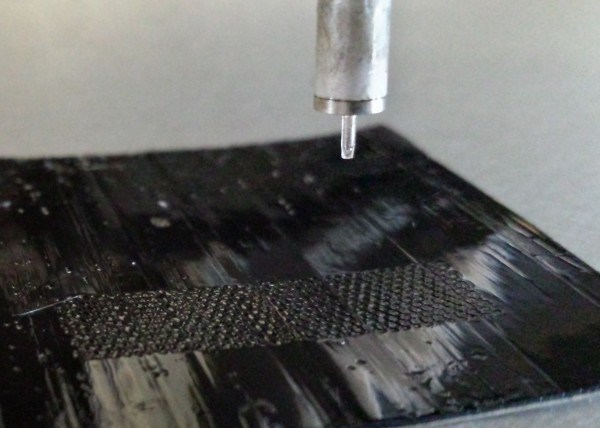

The main scientific areas of the department “Processing of plastics and photographic, nano and polygraphic materials” were formed within the framework of the scientific school “Polymers, Polyelectrolytes, Polymer Composite Materials“, founded in 1996 by doctor of sciences, professor M.V. Burmistr, and works in the following areas:

- synthesis of elementorganic polymers;

- structure, thermophysical properties and relaxation characteristics of ionogenic polymers;

- polymer electrolytes for electrochemical devices;

- nanomaterials based on polyionenes and silicates;

- special purpose composite materials;

- utilization of secondary polymers;

- modification of polymer composite materials.

One of the perspective and progressive directions of the Department is the synthesis of organometallic compounds. Thus, new polyfunctional organometallic monomers and oligomers have been developed, as well as composite materials on their basis, including a new class of carbon-functional silicone alcohols for the production of polyurethane materials having physico-chemical parameters that are not inferior to world standards. The methods of synthesis were developed and the influence of the structure and nature of the substituents on the physicochemical and modifying properties of the obtained compounds was studied.

Areas of use of new elementorganic low molecular weight and oligomer compounds, as stabilizers of polymers, electrolytic and modifying additives are determined. Extended investigations of optimum formulations of composite mixtures based on synthesized compounds have been carried out. Studies have been confirmed by relevant studies of extended research.

Recently, the efforts of scientists and technologists aimed at the creation of polymeric materials with ion conductivity. On the basis of such materials, it is possible to create powerful primary (batteries) and secondary (accumulators) of high capacity and light weight electric power, new generation electrochromic displays and various sensors intended for use. The desirable characteristics of solid polymeric electrolytes (TPE) with metal ion conductivity are high level of conductivity (mainly cationic), the possibility of industrial processing into films with high mechanical characteristics, low glass transition temperature, chemical stability in contact with materials and a wide window of electrochemical stability. The methods of synthesis of a number of new oxyethylene-aliphatic and oxyethylene-alkylaromatic polyionenes of different ionic concentrations with high values of molecular mass have been developed at the department, syntheses have been carried out and 25 different polymers with corresponding molecular structures have been characterized.

Another direction of the Department’s work is to solve the scientific and technical problems of modern technologies in electrochemistry, the urgency of which is due to the need for the synthesis of new thermostable low-temperature ionic liquids, capable of operating in the temperature range from -65 0С to +65 0С, with high ionic conductivity. The importance of research work is also in solving the current problem of chemistry of macromolecular compounds – reducing the cost and environmental purity of synthesized monomers, the possibility of creating on their basis polymeric materials with high ionic conductivity. The present state and main trends of the development of ionic liquids for solving scientific and technical problems of chemistry and chemical technology are considered in the paper. A directed synthesis and systematic study of the properties of ionic liquids based on derivatives of morpholine was carried out. Synthesized low-temperature ionic fluids based on high-ionic conductivity morpholine derivatives are promising compounds of a new type that can be used as: a component of liquid and polymer electrolytes for various electrochemical devices (solar cells, current sources, capacitors, lithium batteries, etc.); for membranes of fuel cells based on polyelectrolytic complexes; extractives, solvents and catalytic environments in organic synthesis and polymer synthesis; immersion media in refractometry; sensory elements for refractometric analysis, etc. New types of ionic liquids based on morpholine derivatives have significantly higher (more effective) ion conductivity compared to previously known compounds at significantly lower glass transition temperature.

The Department has the development of scientific directions that solve the problems of plastics processing industry, tire and rubber industry.

Improvement of the processes of modification of elastomeric materials. It has been established that the chemical structure of modifiers of the type of acloxiaminitotitanates for elastomeric anaerobic compositions has a fundamental effect on the strength of metal-polymer compounds. The physico-chemical characteristics of modifiers, which allow to predict a number of properties, are calculated.

Improvement of the processes of modification of elastomeric materials. It has been established that the chemical structure of modifiers of the type of acloxiaminitotitanates for elastomeric anaerobic compositions has a fundamental effect on the strength of metal-polymer compounds. The physico-chemical characteristics of the modifiers, which allow to predict a number of properties, are aimed at approaching the solution of a specific technical problem, substantially reduce material costs and time during conducting research.

The bases of modification of elastomeric materials by composite additives on the basis of polyguanidinium hydrochloride and oligomeric polyguanidines have been developed, advantages of developed modifiers are shown in comparison with the existing ones on the increase of the complex of properties in rubber reinforced systems. It is shown that the use of oligomeric GHG in the form of alloys with a thickener is promising, and in addition to improving the technical characteristics of rubber, it is possible to solve the issue of GHG amusement and dosage and provide a better graduation form.

It has been established that GHG composite stabilizers help slow down aging of rubber, especially in the presence of diafen AF.

The regularities of elastomeric compositions elucidation with the use of organic acid derivatives of phosphorus and sulfenamide derivatives with various functional groups and substituents are established.

The influence of new quaternary ammonium salts, zinc-containing composite additives on the activation of the vulcanization process and modification of the properties of elastomeric compositions on the basis of carboxylic diene rubbers has been established. It is shown the possibility of their use as multipurpose additives in order to intensify vulcanization processes, modify the properties of rubber, reduce the formation of toxic substances, expand the range of domestic ingredients.

Anaerobic compositions with a high complex of properties for bonding of metal substrates, fixation and sealing of threaded splice joints have been developed.

New polymer composite materials with the increased technological mechanical and tribotechnical properties on the basis of polypropylene and hybrid filler are obtained.

Polymer composite materials based on polypropylene and modified basalt fiber have been developed. The obtained materials are characterized by an elevated level of physico-mechanical properties of the thermophysical properties and can be applied in almost all branches of industry.

An effective way of modifying the secondary polymer materials of a number of polyolefins (polyethylene, polypropylene) in the process of their processing is proposed. It is established that using modifications made on the Department, it is possible to increase physical and mechanical properties to the level of primary polymers.

As a polymer matrix for polymer composite materials, the process of reactive extrusion improved the technology of modification of primary polypropylene. The results of this work showed that the reinforcement of modified polypropylene with mineral and synthetic fibers is a promising direction in obtaining polypropylene based PCM. The application of the proposed modification methods greatly increases the range of physical-mechanical and thermophysical properties.

The effective methods of recycling waste from secondary polyethylene terephthalate (PETF) have been developed.

Departments performed state-funded research work in accordance with the SRW plan of the Ministry of Education and Science of Ukraine. Among the most important works should be noted:

- The project of the State Fund for Fundamental Research of the Ministry of Education and Science of Ukraine No. 03.07 / 164 “Synthesis of new hetero-circuit compounds and polymers, research of physical and chemical bases of modification of elastomeric and polymeric materials”

- Grant of the President of Ukraine GP / F11 / 0043 “Development of nanocomposites based on laminated silicates and polymeric quaternary ammonium salts (ПЧАС) as carriers of modifying additives with an adjustable complex of properties for use in rubber production processes” .- Ukrainian-Hungarian project M100-2007 “Development of polymeric composites reinforced with basalt fibers “(financing of the Ministry of Education and Science of Ukraine)

- Ukrainian-Bulgarian project “Solid polymeric electrolytes based on polymeric quaternary ammonium salts for lithium current sources” (financing by the Ministry of Education and Science of Ukraine).

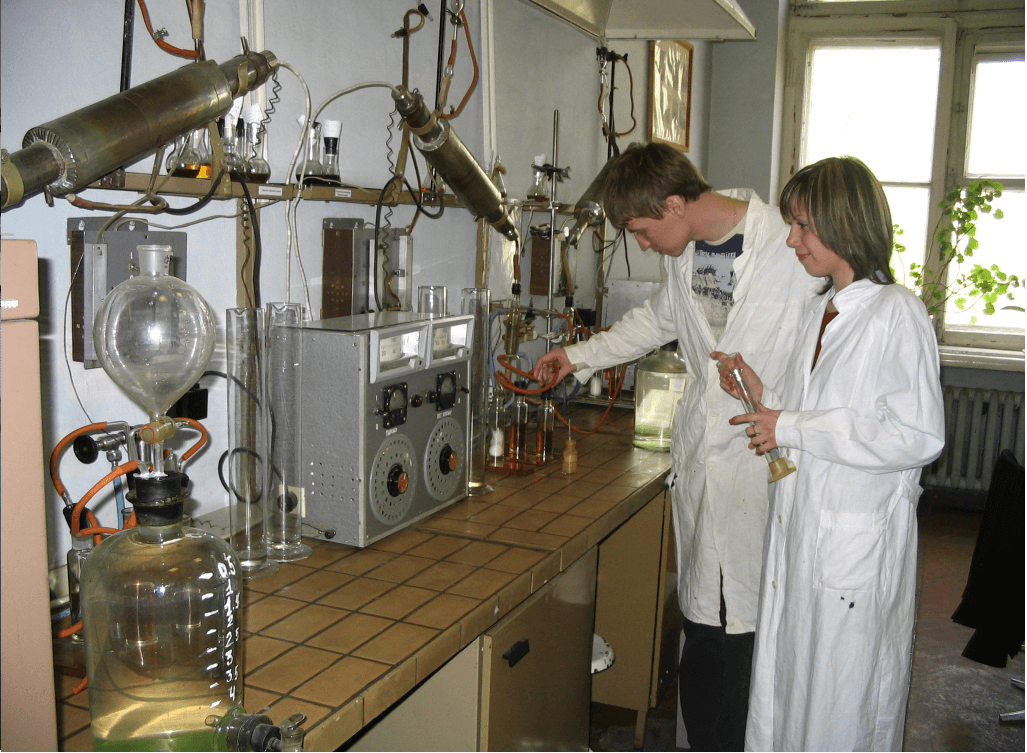

During the period from 2007-2011, state-funded research work was carried out with the involvement of 3-5-year students. The result of such cooperation is annual protection of diploma research works (not less than ten), participation of students in international conferences of young scientists, graduate students and students, and in the All-Ukrainian sectoral competition of the best diploma projects and works.

The Department of Fuel Materials has IV level of accreditation, trains specialists in bachelor’s and a master’s degrees

specialty 161 Chemical technology and engineering

specialization Chemical technology for educational programs:

Chemical technologies of fuel and carbon materials,

Chemical technology of alternative energy resources.

Licensed set – 60 students, training period – 5 and a half years. Students study full-time and part-time, as well as in accordance with an individual program of exterior.

For persons who have higher technical education in other directions, the Department carries out retraining on the reduced program on the basis of the curriculum of the specialty “Chemical technologies of fuel and carbon materials”

At the end of the study, graduates-bachelors get the qualification of “technologist”, masters – “engineer-technologist” and “teacher of higher education” and “engineer-researcher”.

PLACES of WORK for GRADUATES

Kyiv

- PJSC “Ukrnafta”

- State Enterprise of UkrNII Oil Refining Industry “MASMA”

- JSC “Synthesis-group”

Dnipro

- KHV PJSC “Evraz-DMZ”

- Nizhnedneprovsk oil tank

- PJSC “Southern machine-building plant”, application of oils.

- Laboratory of aviation fuels of the airport “Dnipropetrovsk”, “Dniproavia”.

- TD “Introil”

- National Alliance-Ukraine

- Agro Union

Dnipropetrovsk Region

- Kamianske, JSC “Dniprodzerzhinsky Coke Plant”

- Kamianske, JSC “EVRAZ-YuzhKoks”

- Kryviy Rih, OJSC ” Mittal-Steel Kryvyi Rig”

Poltava Region

- Kremenchuk, PJSC “Transnational financial and industrial oil company” UkrtatnaNafta “

- GPU “Poltavagasvidobuvannya” Solokhivskaya fishery “

Odessa

- PJSC “Odessky Refinery”

Lisichansk, Luhans’ka obl.

- “Lisichansk oil investment company” (“Lisichansk oil refinery”)

Zaporizhzhia Region

- Berdiansk, JSC “AZMOL”

- Berdiansk, RU “Arrinol”

- Zaporizhzhia, JSC “Zaporozhye Electric Locomotive Repair Plant”

- Zaporizhzhia, PJSC “ZaporozhCox”

Lviv Region

- Drohobych, NPC “Halychyna”

- Dashawa, Lviv region., Dashavskaya VUUPZH

Sumy Region

- Mala Pavlivka, Kachanivsky gas processing plant, UKRNAFTA OJSC

Ivano-Frankivsk Region.

- Nadvirna, JSC “Naftohimik Prykarpattya”

- Dolina, Dolinsky gas processing plant, PJSC “Ukrnafta”

- Boryslav, Borislavsky GPP, PJSC “Ukrnafta”

Kharkiv Region

- Andriivka, DK “Ukrgazvydobuvannya”, Shebelinsky department of gas processing, gas condensate and oil

- Red Donetsk, DK “Ukrgazvydobuvannya”, Gas Industry Department “Shebelinkagasvidobuvannya”

Chernihiv Region

- Varva, OJSC Ukrnafta, “Gnidintsy gas processing plant”

During the existence of the Department, its team, in cooperation with industry institutes and rubber industry enterprises, is working on solving urgent problems in the field of creating new types of rubber and composite materials based on elastomers.

The most important theoretical and practical researches are devoted to actual problems of vulcanization of rubber, the mechanism of action of accelerators of vulcanization, search of new vulcanizing systems, modification of rubber, creation of special types of rubber for bus, rubber, gas, metallurgical, cable and other industries.

For the first time the works on the implementation of the system of white soot and the complex RU for the significant increase in the strength of bonding tire rubber with textile cord. The developed system, known as HRH, has been widespread throughout the world.

At the metallurgical enterprises, a rubber cartridge container was introduced instead of a metal for transporting hot metal samples for rapid analysis from a blast furnace or martin to a pneumatic post over the pipeline, which greatly reduced the weight of the container and noise during its transportation.

The scientific and technical bases of application of modifying systems in multilayered rubber-reinforced composites have been developed (Dr. Vashin Y.M.). The basic directions of creation of modifying systems, which provide concentration of functional agents on the boundary of phase separation in the elastomeric matrix, are determined. It allows to effectively regulate the adhesion and anti-adhesion properties of human-reinforced systems, the properties of compositions based on rubbers of different polarity, the characteristics of multilayer systems of the type “vulcanizate-rubber compound”. On the basis of the principles developed, a whole series was created by modifying the systems and technologies of their application in elastomeric materials, including those with secondary raw materials; layered adhesive compositions for the repair of automobile tires, including SVGSH and VGSH, were developed; developed by modifying the compositions regenerating for the surface treatment of rubber crumb for its efficient use in the composition of tire rubber and rubber for RTI. In addition, the use of the principles of transport synergism developed complex stabilizing additives that significantly reduce the content of traditional ingredients in the composition of tire rubber and rubber for footwear and molded RTI.

On the basis of the developed principles, a number of technologies have been created that allow solving environmental problems through the efficient utilization of rubber waste.

The principles of formation of geometric phase morphology of elastomeric materials were first determined at the department. They became the basis for the development of new representations on the determining role of geometric parameters in the properties of polymer materials (Dr. N.M. Yevdokimenko). Based on the application of the Ferhülst model using percolation analysis, the influence of different components of rubber mixtures on the phase morphology of materials has been studied. The method of evaluation of morphological structure parameters is developed. The obtained data allow to effectively regulate the complex of properties of elastomeric materials.

Intensive development direction, initiated by the professor, D.Sc. Kutyanina VS, concerning the creation of composite ingredients of various purposes, which are used for the manufacture of rubber mixtures in the tire and rubber industry. The use of such components allows one side to improve the complex of technical properties of rubber, and on the other – to partially or completely replace the scarce and valuable ingredients in the composition of rubber mixtures. Such additives as the modifier BR, Aminol, Aminofen and others. Serially produced for the needs of the rubber industry (Ph.D. Tereshchuk M.M., Ph.D. Levanyuk)

One of the main areas of research of the department is glue and adhesives of various purposes (Dr. Ye. Y.R., Ph.D., Zibaylo S.M.). The application of new approaches, including the calculations, allowed the creation of a series of adhesive compositions for use in various industries at the level of the best world counterparts.

In addition, highly concentrated low-viscosity adhesive compounds for use in the furniture industry have been developed (candidate of technical sciences Vashchenko Yu.M., Dr. Sci. Yevdokimenko N.M.).

The continuation of works begun under the leadership of G. A. Bloch is the development of ideas about the mechanism of action of the multifunctional components of the vulcanizing group – sulfuric, nitrogen and phosphorus-containing compounds (Dr. V. Ovcharov). Recommendations on the use of FOS as accelerators of sulfuric vulcanization of elastomeric compositions based on diene rubbers in order to intensify vulcanization processes and energy saving in the production of more high-quality rubber products, reducing the formation of toxic and carcinogenic compounds, expanding the range of in ediyentiv. Using the studied FOS, sulfuric vulcanizing systems were created for elastomeric compositions for the manufacture of tires, rubber-technical products, cable products, rubber footwear. In addition, work continues with the use of natural fillers and their modification by surface-active compounds with the formation of nanostructures in elastomeric materials.

In recent years, the possibility of using as a component of rubber mixtures a wide spectrum of action of by-products of production of phenols from coal-tar, containing various derivatives of phenols, is studied. The polyfunctionality of the FD product on the basis of phenol derivatives and the positive effect on the properties of tread rubber for tires of various applications are shown. Increased strength and resistance to thermal aging, increased resistance to cracks formation and fatigue wasting have been established. Also defined is the action of quaternary ammonium salts, synthesized from available raw materials (urotropin and benzyl chloride), as well as on the basis of raw materials of plant origin (castor oil or furfural). It is shown that compounds with quaternized nitrogen atom (quaternary ammonium salts) are not only a component of intercalated layered silicates of elastomer nanocomposites, but also effective vulcanizing active ingredients of elastomeric compositions based on diene rubbers. The perspective direction of their receipt is the synthesis on the basis of renewable bio-raw materials. The influence of carboxyl-containing polyguanidinamines on processes that take place in a rubber-metal-metal system is investigated. The high efficiency of the carboxyl-containing polyguanidines as rubber adhesion promoters to the brass metal cord is shown.

The research was conducted to reveal the patterns of correlation of deformation-strength, tribotechnical and technological properties of block polyurethanes with parameters of structural organization of various levels. The system of epoxy + phenol formaldehyde resin for modifying block polyurethane has been investigated. Curing systems for different types of epoxy oligomers are investigated. It has been shown that the evaluation of the activity of modified polyamines and their mixtures in the hardening of epoxy resins should be carried out at the maximum temperature of the exothermic reaction of the interaction of epoxy groups of resins and amine groups of hardeners.

Considered the possibility of using waste in the manufacture and operation of rubber with the use of various polyfunctional compounds. The expediency of the use of modified regenerates on the basis of rubber waste produced by GTP on the basis of fluoroelastomers is shown, since the cost of products decreases, and the resistance to aggressive environments increases. It has been shown that modified regenerates can be effectively used up to 50 ppm. for the manufacture of GTP, which are operated under the conditions of various aggressive factors, rubber based on SKF-26 rubber, with both amine and bisphenol vulcanization, as well as on the basis of rubber SKF-32 with catalysed salicylaluminum and non-peroxide radical type vulcanizing system.

Epoxy wear-resistant composites and polyurethane blocks with high viscoelastic properties and thermostability have been developed.

Rubber was developed using modified regenerate, obtained from wastes produced by rubber-technical products based on fluoroelastomers, which have increased thermochemical resistance.

The influence of the molecular structure of silicon-based apretes on the strength of the rubber-based rubber on the basis of the SCPE to the steel of St.3 during vulcanization was investigated. The influence of the order of application of the paper and the coating glue on the strength of the rubber-metal compounds has been established and it is recommended to apply two layers of coating glue over the layer of silicon containing a radical residue of polyoxypropylene glycol with a molecular weight of 400.

The technological features of the use of methyl esters of fatty acids obtained from raw materials of vegetable origin are considered for processing of the surface of crushed vulcanizate, which allow to regulate both the properties of composite materials, and to choose technological processing scheme taking into account the existing equipment and energy consumption.

The results of the research showed the benefits of experimental activators based on the fatty acid ester obtained on the basis of raw materials of plant and animal origin, manufactured according to optimal technological parameters, compared with the traditional system of activators.

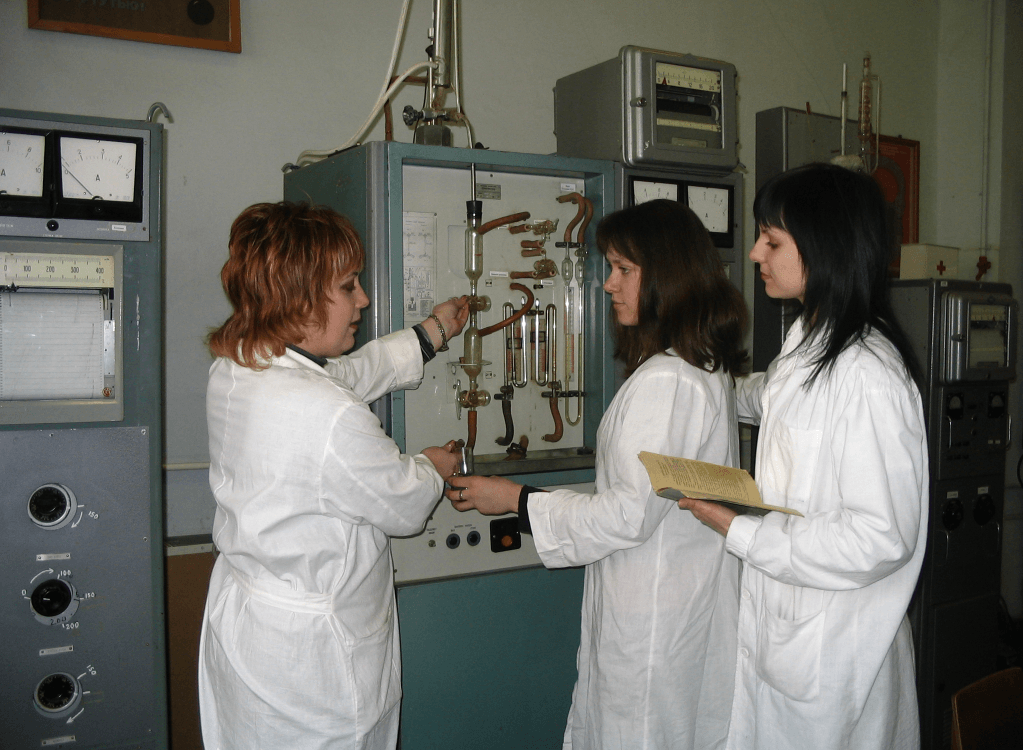

Scientific activity at the Department is closely connected with the creative interests of students. The most capable students are involved in conducting research on the main scientific areas of the Department, participating in works of republican and international conferences of students and young scientists, participating in various contests.

The research results of the Department’s staff are constantly reported at scientific and technical conferences of different levels in Ukraine, Russia, Germany, Poland, Bulgaria. Relevance of the conducted researches is confirmed by received more than 220 certificates of authorship and patents. The staff of the department published more than 900 articles and 20 monographs, some of which were published in the UK.

The Department is also the organizer of the traditional Ukrainian scientific and technical conferences of rubberers, during the years of independent Ukraine, 10 scientific and technical conferences with international participation were held.